Leave your carbon shoes at the door

When is a door not a door? When it has a large carbon footprint – then it’s just a statistic.

The further humans progress into the future, the more resources we burn. The earth could only sustain us and our decadence for so long before we had to make amends. Consequently, sustainability is today on lips and minds across industries worldwide.

There’s no mystery surrounding the source of data about environmental impacts within the construction industry. The problem was that for a long time, that data didn’t have an outlet.

‘‘As industry and the public became interested in carbon footprints and life cycle assessments, the need for some kind of standardised data system became clear,’’ says Stephen Mitchell, chair of the Australasian EPD Programme and principal consultant at Stephen Mitchell Associates.

Enter the environmental product declaration (EPD). In the late 1990s, a system that would quantify a product’s environmental impacts was conceived in Sweden.

That system evolved over time to become the environmental product declaration, an internationally standardised assessment of a product’s environmental impact based on a consistent set of rules developed through stakeholder consultation.

‘‘You can think of the EPD as a summary of a product’s life cycle assessment,’’ Mitchell says.

Barbara Nebel, managing director of thinkstep Australasia, says there was a public demand for the kind of information an EPD provides.

‘‘The Paris Agreement put global warming on the world’s radar, and EPDs are a way to take action,’’ she says.

‘‘Before EPDs, there was no real public outlet for data about environmental studies related to building. Now, an EPD provides us with quality, comprehensive data that’s been independently verified.’’

A product’s environmental impacts are based on a variety of considerations, including energy consumption, emissions and waste generation over its life cycle.

‘‘There’s much more than just a carbon footprint in an EPD,’’ Mitchell says.

Australia’s entry into the EPD system came in 2014, an initiative of the timber industry.

‘‘It saw an opportunity to provide the kind of information builders and architects could use to make smart design choices, so various entities within the industry joined forces,’’ Nebel says.

‘‘They raised the profile of not just EPDs, but the timber industry as well.’’

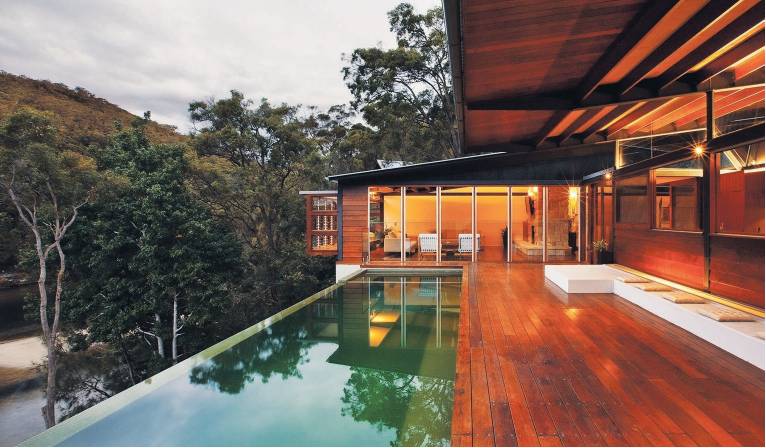

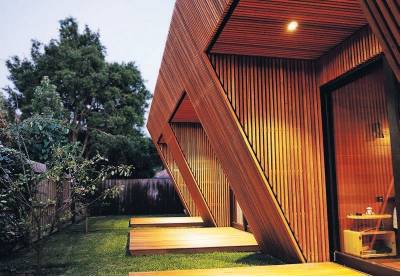

Timber, in particular, has enjoyed a construction renaissance in the last 20 years thanks to greater understanding of its applications.

As the co-author of six timber EPDs, Mitchell says the wood provides the perfect example of the viability of the system.

‘‘EPDs are used to understand and ultimately improve environmental impacts of building resources because the data clearly tells us the story,’’ he says.

With clear and accurate data now on the table, inevitably comparisons will be made between resources. One might assume that steel has a higher carbon footprint than timber, but thanks to EPDs it’s never been easier to verify.

‘‘Timber has such a low carbon impact, it’s actually better than carbon neutral,’’ Mitchell says. ‘‘Throughout timber’s lifespan it absorbs carbon dioxide, and that offsets the minimal carbon expenditure required when it’s processed.’’

‘‘In the case of timber, that data tells us that from an environmental point of view, there’s no better building material.’’

Since the Australian introduction of EPDs, Mitchell says there’s been significant uptake. Big producers in the steel and painting and coating manufacturing industries are on board, and the door swings both ways.

‘‘An EPD allows a producer to be as transparent as possible about their environmental impact because it’s not a rating system,’’ Mitchell says.

‘‘It can be seen as a bit of a risk for these companies because the results may not be flattering. It’s just the facts. There are no value judgments.’’ Any judgments or comparisons can then be made by the end user, whether they’re consumers, sustainability rating systems, and the industry itself. ‘‘Companies like LendLease are using EPD data to make sustainable decisions, and rating systems like Green Star use EPDs to make their assessments,’’ Mitchell says. ‘‘The cement industry is looking at a coal-less future on the back of EPD data.’’ Project teams can use EPDs to earn Green Star points or credits in the Infrastructure Sustainability Council of Australia’s rating scheme. ‘‘And it’s all down to the credibility of the data and particularly the transparency of the producers, which is to be commended.’’ Given that the EPD assesses a product’s entire lifecycle, the data can even be used when considering end-of-life options including recycling and disposal. Eventually, Mitchell hopes the EPD will be embedded into government building regulation processes. ‘‘It’s voluntary at the moment to include any EPD data in those processes within the built environment, but in Germany it’s mandatory.’’ In a promising sign of the future, EPDs are also increasingly required in tender documents. ‘‘The EPD is a long game,’’ Mitchell says. ‘‘It will take a while to develop, but we’re getting more take-up now than ever, and for producers, it’s a great reward for their transparency.’’