The many benefits of remediation

From toxic soil in Victoria’s under-construction West Gate Tunnel to cleaning up former gasworks around the country, environmental remediation is a sector on the rise in Australia.

Improving environmental protections – such as federal waste plans, tightening regulations in almost every state over the last year for water and land rehabilitation – and a growing population have led to a requirement to unlock contaminated land for future development in the most sustainable way possible.

As the industry grows, so does the opportunity to not just treat new and emerging contaminated materials but also recycle them into the increasingly important circular economy.

The Australian waste remediation and materials recovery market is forecast to touch $4.9 billion in 2022 and grow faster than the gas, water, electricity and waste services sectors, placing it on par with the heavily government-supported local space industry.

With water and soil remediation being relatively mature markets in terms of technologies, the growth opportunity is in finding ways to reuse waste streams – such as those created by the commercial, industrial, construction and demolition sectors, which make up 80 per cent of all waste materials, according to the Australian government’s National Waste Report 2020.

The report found that, in terms of materials recovery, the highest rates were from metals (90 per cent) and masonry materials (82 per cent).

Ash and hazardous waste had the lowest rates of recovery at 47 per cent and 30 per cent respectively, leaving considerable space for companies with advanced technologies and experience to lift these figures.

‘‘By-products from waste-to-energy facilities, such as the ash that comes from burning municipal household rubbish, which makes up 15 per cent to 25 per cent by weight of the input feed, can be treated or integrated into other products,’ says Ben Kay, innovation manager at Enviropacific, Australia’s leading specialist environmentally focused services provider.

‘‘There are no waste-to-energy facilities online here yet, but Europe has been doing it for years so we are looking at technologies from our international partners that we can use to repurpose the by-products when they do come online, integrating them into building products, for example.’’

For the current market, Enviropacific brings a range of innovative applied science and engineering solutions to three key specialist areas: remediation, water treatment and hazardous waste management.

It has completed more than 4000 projects to date for clients including the Department of Defence, state transport authorities and the likes of Lendlease and BP. The company incorporates an element of sustainable remediation into every project it completes.

Complex projects such as the clean-up of an illegal dumping site in Kaniva, Victoria, or treating heavily contaminated water at the former industrial site of Barangaroo in Sydney require specialist companies such as Enviropacific to deal with the consequences of historical and ongoing contamination.

The goal is to divert from landfill and ensure that, at the end of the remediation process, the land is ready for beneficial re-use for infrastructure or property development.

Kay says treating soil contamination on-site is most common, as it allows the site to reuse it without buying new materials.

‘‘More of a challenge is taking a waste stream and integrating that into a new product, as there are significant hurdles around regulatory approvals and ensuring there is no future impact on the environment or community from these materials,’’ he says.

The challenges of the removal of contamination from water are different.

‘‘We have a ‘massive’ water treatment team that can handle everything from major tunnelling work and PFAS treatment to residential basement excavations,’’ says Will Magnus, Enviropacific’s project development manager. ‘‘This water is treated and can be reused on site, such as for dust suppression, but can even be resurrected as drinking water, depending on the client’s requirement.

‘‘Reuse is where the growth opportunity is, particularly in industrial waste. We know this is an area where the industry is going.’’

To this effect, in December 2021, Enviropacific commissioned a new non-destructive digging (NDD) plant at SOLVE Altona, in Victoria, that takes waste from hydro excavations which otherwise may have gone to landfill. The NDD plant separates the slurry into materials that can be reused – sand, clay and aggregates – as well as water that is then reused in the adjoining thermal treatment plant.

‘‘Anything which is identified as contaminated can be sent to our thermal treatment plant which then completely destroys the contaminant,’’ says Dino Adikaram, SOLVE business manager.

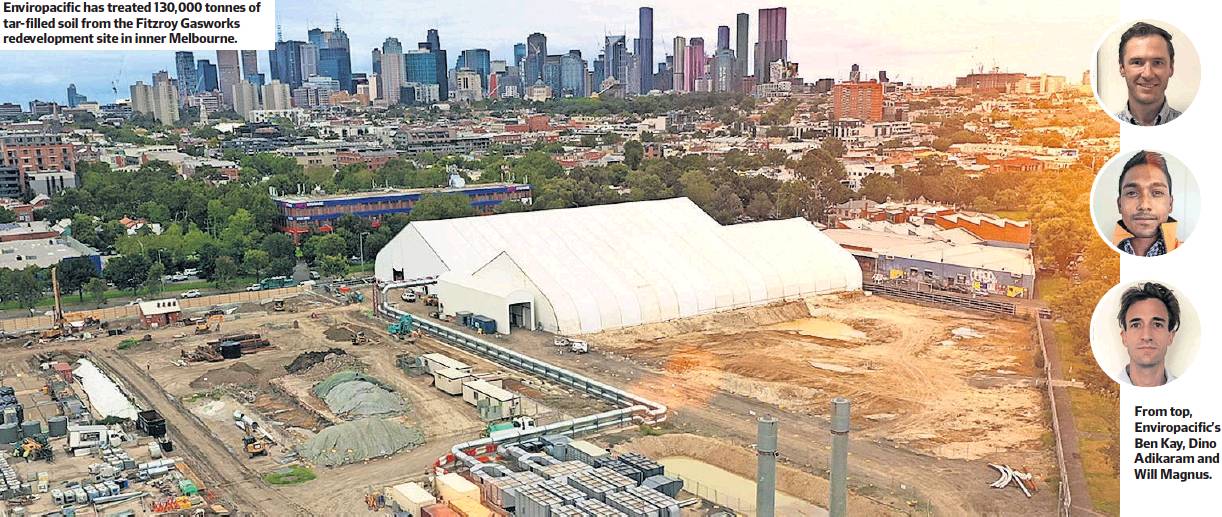

The thermal plant alone can treat up to 100,000 tonnes of hazardous waste a year for reuse as road bases and industrial fills. Notably, it treated 130,000 tonnes of tar-filled soil from the Fitzroy Gasworks redevelopment site in Melbourne.

As a company whether it be on-site soil remediation, water treatment or treating hazardous waste at SOLVE, Enviropacific is reducing the amount of PFAS and other contaminated materials going to landfill.

Enviropacific’s focus on preventing, stopping, and reversing environmental damage is part of a growing shift, both economically and socially, to make environments and communities safer and healthier.